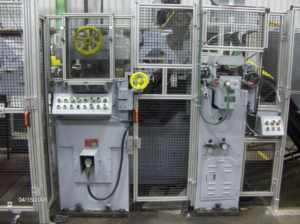

Custom Mechanical Guarding Solutions

Turnkey Safety for Every Machine

In industrial environments, mechanical guarding is more than just a compliance checkbox — it’s a critical layer of protection for your people, your equipment, and your productivity.

While many providers offer prefabricated, one-size-fits-all guards, Arrow Industrial Solutions takes a different approach.

Every guard we produce is custom-designed, engineered, and fabricated for the specific machine and process it will protect — no generic panels, no ill-fitting retrofits. We deliver turnkey mechanical guarding solutions that integrate seamlessly into your operations, ensuring safety, compliance, and efficiency from day one.

Get Started Now!

Why Choose Custom Mechanical Guards Over Prefab?

Prefab guards often require costly modifications, can leave hazardous gaps, or interfere with machine access and maintenance. Arrow’s custom mechanical guarding eliminates these challenges:

Whether you’re safeguarding a single press or an entire production line, our mechanical guarding solutions are built to work as hard as you do.

Our Turnkey Mechanical Guarding Process

From concept to compliance, our team can handle every step:

Industrial Solutions handles every step:

On-Site Assessment

We evaluate your machines, hazards, and workflow requirements.

Custom Design

CAD-modeled guarding solutions tailored to your exact needs.

Fabrication

Precision manufacturing in our state-of-the-art facility.

Installation

Professional fitment to ensure optimal protection and usability.

Testing & Validation

Functional checks to confirm performance and regulatory compliance.

Mechanical Guarding Products & Features

Every guard is designed with operator ergonomics, ease of maintenance, and operational efficiency in mind. Our custom guards can incorporate a range of safety features and components:

Our services include:

Industries We Serve

We deliver custom guarding systems engineered to meet the safety and operational needs of a wide range of industries. While we highlight some of the industries we serve below, our solutions can be tailored to fit virtually any facility, protecting workers, streamlining production, and ensuring compliance wherever they’re needed.

Manufacturing & Production

Automotive Assembly Lines

Food & Beverage Processing

Pharmaceutical Manufacturing

Electronics Assembly

Heavy Industry & Machinery

Metal Fabrication & Machining

Material Handling & Logistics

Aerospace Component Manufacturing

Packaging and Bottling Operations

Energy & Utilities

Power Generation Plants

Oil & Gas Facilities

Water Treatment and Distribution

Mining Operations

Protect Your People and Your Productivity

Investing in custom mechanical guarding is an investment in uptime, safety, and peace of mind. Whether you’re upgrading an existing line or designing a new process, Arrow Industrial Solutions has the expertise and capabilities to deliver guards that work for your operation — not against it.

Our solutions go beyond mechanical guarding — we also design and integrate control reliable guards and electrical guarding to create a complete safeguarding system. Together, these layers of protection help ensure your machinery is compliant, efficient, and safe.

Contact us today to schedule your on-site assessment and see how our turnkey guarding solutions can safeguard your team and your bottom line.