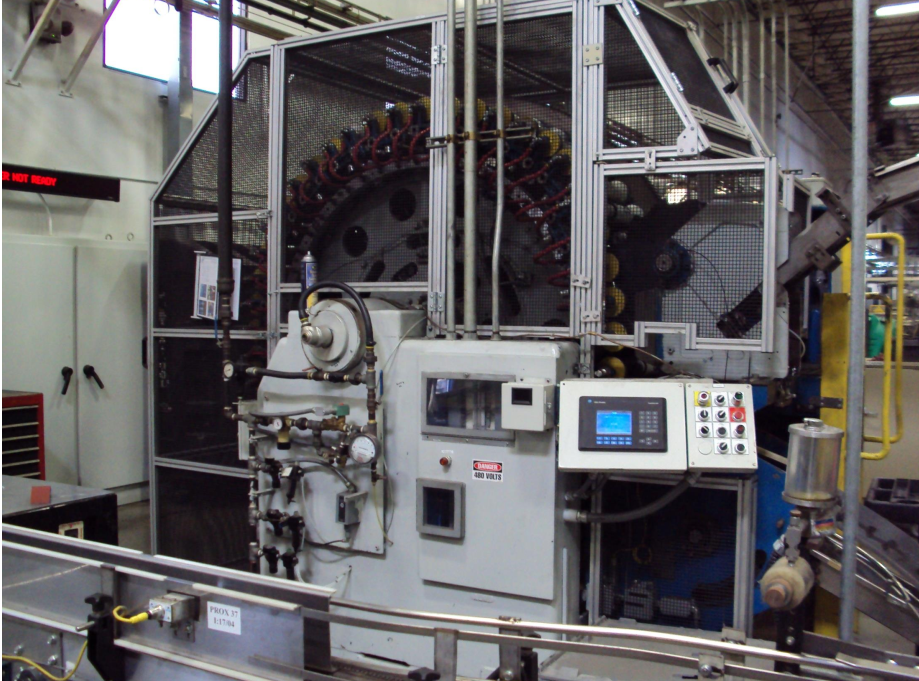

Custom Welded Steel Mechanical Guarding

Heavy-Duty, OSHA-Compliant Protection Built for Your Machines

When your machinery operates in high-risk, high-duty industrial environments, you need guarding that can withstand the toughest conditions.

Unlike generic prefab options, Arrow Industrial Solutions designs, fabricates, and installs welded steel guards engineered specifically for your equipment and hazard zones. We deliver turnkey mechanical guarding that provides maximum strength, safety, and compliance — without compromising operator access or productivity.

Get Started Now!

Why Choose Custom Welded Steel Guards?

Prefab guards often require costly modification, can leave hazardous gaps, and may not stand up to continuous use. Our custom steel guards are built for the exact machine they’re protecting, ensuring:

Our Turnkey Mechanical Guarding Process

From concept to compliance, Arrow Industrial Solutions handles every step:

On-Site Assessment

TÜV-certified engineers and licensed PEs can assess your equipment, identifying hazard zones and compliance gaps.

Custom Design

CAD-modeled, incorporating ventilation, inspection access, and ergonomic considerations. Structural integrity validated via FEA (Finite Element Analysis).

Fabrication

In-house welded construction using mild steel, stainless steel, or galvanized steel. Optional powder coating, painting, or specialty finishes for corrosion resistance.

Installation

Guards installed for precise fit and integration with interlocks, safety switches, and control systems.

Testing & Validation

Functional safety testing, compliance verification, and OSHA-ready documentation.

Ideal Applications

Our custom welded steel guards excel in applications such as:

Build Your Custom Welded Steel Guarding System

Whether you’re outfitting a new line or retrofitting existing machinery, Arrow Industrial Solutions will design and install welded steel guards that meet your exact safety and operational requirements.