Custom Electrical Guarding Solutions

Turnkey Electrical Safety Systems

Whether you’re building a new line or retrofitting existing equipment, we deliver the expertise, technology, and project management needed to get safety right the first time.

In today’s automated manufacturing environment, electrical machine guarding isn’t optional—it’s essential. From robotic cells to conveyor systems, electrical safeguarding components prevent hazardous motion, protect operators, and keep facilities in compliance with OSHA, ANSI, ISO, and NFPA standards.

Arrow Industrial Solutions provides turnkey electrical guarding services, handling every stage of the process—from assessment and design to integration, testing, and compliance documentation.

Get Started Now!

Why Invest in Turnkey Electrical Guarding?

Electrical guarding systems are most effective when designed, installed, and validated as a complete solution. Arrow’s turnkey approach means:

Our Turnkey Electrical Guarding Process

From concept to compliance, we can handle every step:

On-Site Assessment

We evaluate your machines, hazards, and workflow requirements.

Custom Design

CAD-modeled guarding solutions tailored to your exact needs.

Fabrication

Precision manufacturing in our state-of-the-art facility.

Installation

Professional fitment to ensure optimal protection and usability.

Testing & Validation

Functional checks to confirm performance and regulatory compliance.

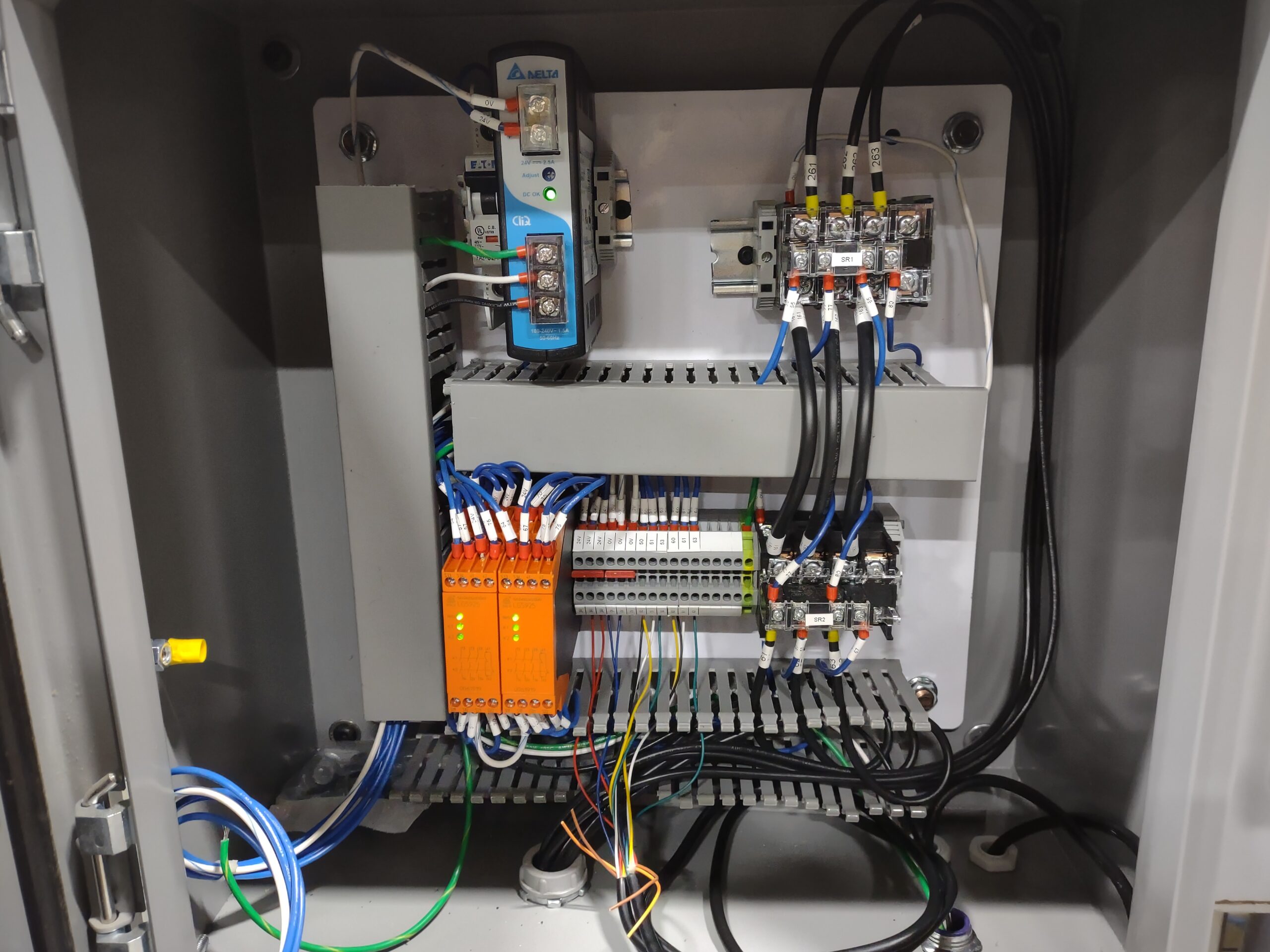

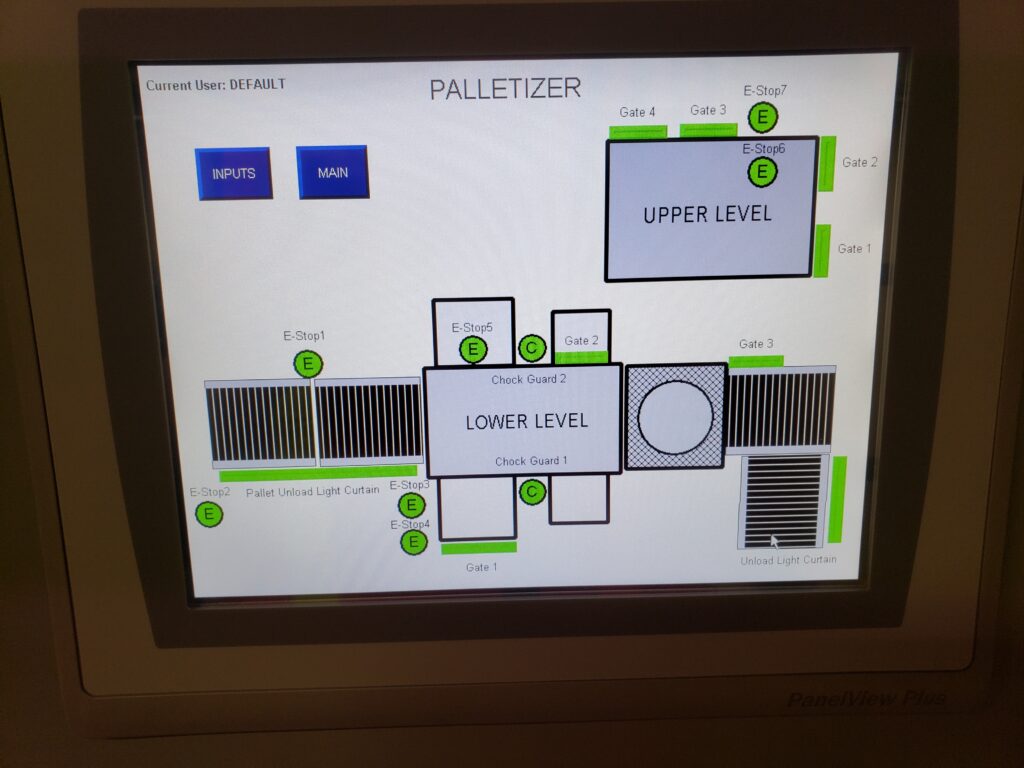

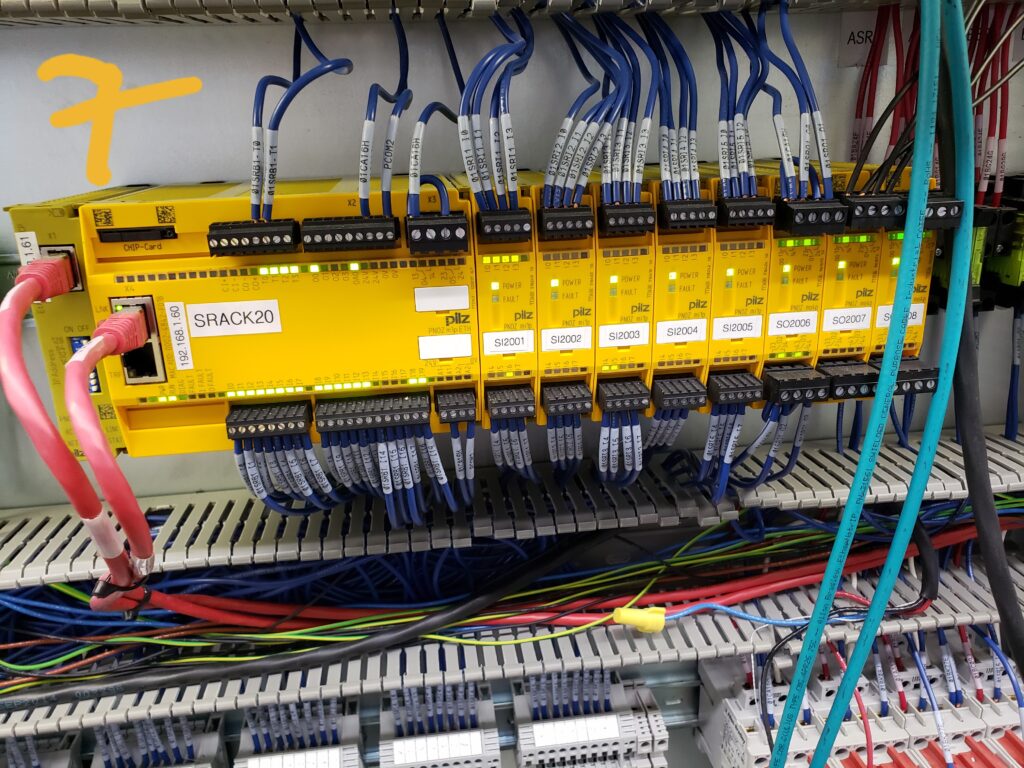

Core Electrical Guarding Components

We integrate advanced safety devices and controls tailored to your application:

Industries We Serve

We deliver custom guarding systems engineered to meet the safety and operational needs of a wide range of industries. While we highlight some of the industries we serve below, our solutions can be tailored to fit virtually any facility, protecting workers, streamlining production, and ensuring compliance wherever they’re needed.

Manufacturing & Production

Automotive Assembly Lines

Food & Beverage Processing

Pharmaceutical Manufacturing

Electronics Assembly

Heavy Industry & Machinery

Metal Fabrication & Machining

Material Handling & Logistics

Aerospace Component Manufacturing

Packaging and Bottling Operations

Energy & Utilities

Power Generation Plants

Oil & Gas Facilities

Water Treatment and Distribution

Mining Operations

Protect Your People and Your Productivity

Investing in custom electrical guarding is an investment in compliance, productivity, and worker safety. Whether you’re retrofitting legacy equipment or implementing new automation, Arrow Industrial Solutions delivers engineered guarding systems that integrate seamlessly with your operation.

Our expertise goes beyond physical barriers — we specialize in control-reliable electrical safeguarding, including gate switches, interlocks, dual-palm devices, and zero-motion detection systems. When combined with our mechanical guarding solutions, these layers create a comprehensive, standards-compliant safety system tailored to your facility.

Contact us today to schedule an initial assessment and discover how our turnkey electrical guarding solutions can help protect your workforce, reduce downtime, and strengthen compliance.